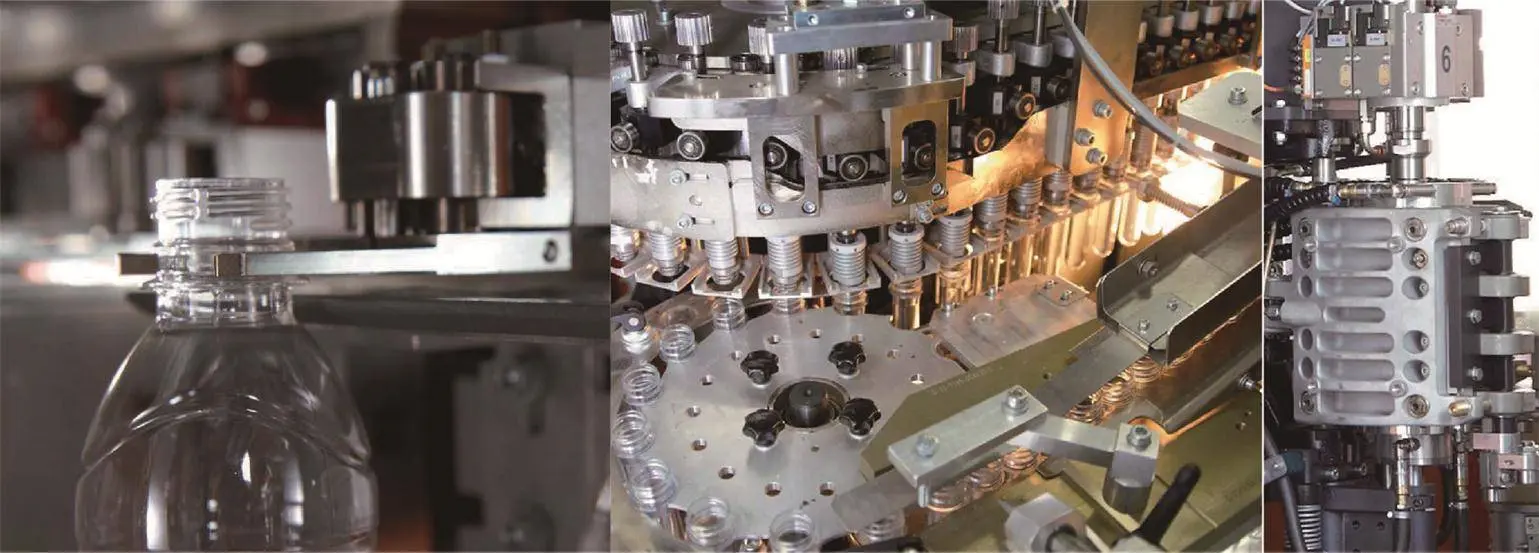

DMK-R Serisi Rotary PET Şişirme Makinası

- ● 6-22 cavities, 12000-48000bph,max. 2.5L,

- ● 2,200 bottles/cavity/hour

- ● Provide unique design for instant mould conversion

- ● The new mould base concept reduces format changeover times.

- ● Cut 30% blowing costs, reduce 46% power consumption.

SML Serisi Servo PET Şişirme Makinası

● Cavity: 4,6,8; Output: 6500-14500 bph; Volume: 0.3-1.5L;

● Stretch by servo motor, more precision and easy to adjust.

● Using continuous heating full servo control.

● Spindle chain small pitch saving more then 50% power compare with other machine.

DBS Serisi Tam Otomatik PET Şişirme Makinası

● Output: 2000-11000 bph

● Volume: 0.3-2L

● Cavity: 2-9

● Material: PET

● Form: Full Automatic PET Stretch Blow Molding Machine

DBH Elle Beslemeli Otomatik PET Şişirme Makinası

● DBH Series

● Output: 500-2500 bph, Volume: 0.3-5L

● Cavity: 1-3

● Material: PET

● Form: Hand Feeding Preform Blowing Machine

SBL Serisi Büyük Şişelere PET Şişirme Makinası

- ● Max. 5-20L, 2-6 Cavities,For Big Edible Oil or Water Bottle

- ● Good stability, Competitive price

- ● Demark machinery is the first company that makes the single cavity capacity up to 700 bottles per hour(take 20L oil bottle for example)

SFL Serisi Servo Pet Şişirme Makinası

Turnover Servo: to change the position of preform upside down.

Oven Servo: drive the main chain in the oven

Stretch Servo: drive the stretch rod to make precisely stretch

Transfer Servo: take out the bottle when finish blowing

SFL-PP Serisi Şişirme Makinaları

- ● Material: PP

- ● 6,10,12,16 cavities, 4500-18000bph,max.0.5L PP bottle

- ● High production

- ● Low energy consumption

- ● Quality bottle

PET Şişirme Makinası Revize Projeleri

● Retrofit of bottle and preform production systems to realize the conversion among different neck finishes such as 2925, 3025, PCO 1810/1881, PCO, 1716, 2622 …

● Modify structure of blowing mold and blowing machine parts to realize universality among different brands(KRONES, SIDEL, KHS, SIPA, SIG…) of blowing system.